How our refurbishment service works

Following initial approach from customer, Somerford will arrange for our experienced engineers to carry out

a full preliminary vehicle inspection and assessment ready for road marking vehicle refurbishment.

This includes an analysis of salvageable equipment suitable for refurbishment or repair, items which will require replacement,

and areas of recommended upgrade to incorporate updated legislation or safety recommendations.

Our communication with customer will establish budget and agree scope of works.

Stage 1:

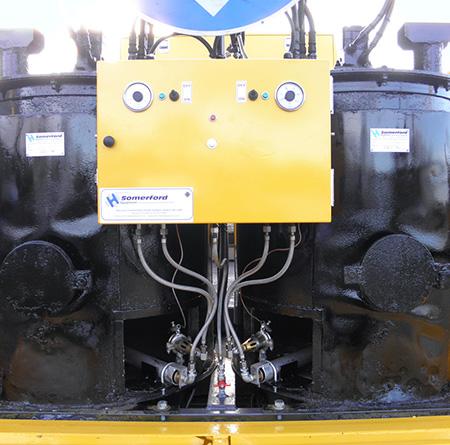

All equipment is removed from the vehicle body and refurbished,

repaired or replaced as required

Stage 2:

Agreed equipment upgrades or additions are incorporated

Stage 3:

Bodywork and chassis are shotblasted and refinished

Stage 4:

Rewiring is completed

Stage 5:

Upgrades carried out as required to lighting, signage and high visibility markings

Stage 6:

Health & Safety upgrades installed, such as anti-slip flooring,

raised side rails to meet working at height legislation etc

Stage 7:

Servicing & inspection works carried to include gas safety checks, testing and certification

Stage 8:

Final testing of all systems and in-house pre delivery inspections completed

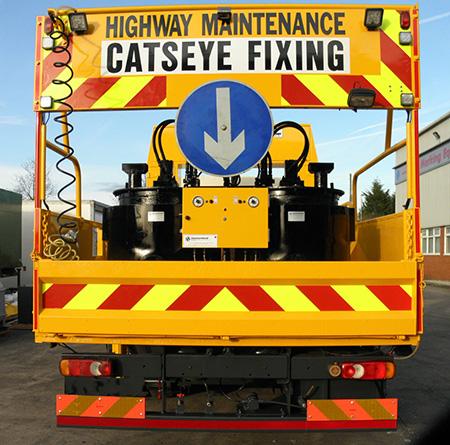

Previous Work

Here at Somerford Equipment we understand that budgets do not always allow for brand new machinery.

Refurbishing an existing chassis can prolong the lifespan of an existing vehicle while also keeping budgets healthy.

Below you can see a range of our previous refurbishment works.

Before

During

After

Before

After

Before

After

Before

After

Before

After